EPAG Performance Overview:

| Classifiction | Car Display | PAD panel | laptop panel | Reader panel | Industrial control/education large screen | Phone back cover |

| Haze(%) | 3-8 | 6-12 | 8-16 | 15-25 | 20-35 | 25-45 |

| Classifiction | Phone back cover | Industrial control/education large screen | Reader panel | laptop panel | PAD panel | Car Display |

Gloss (Gu)

60° angle test | 10°-35° | 25°-45° | 45°-65° | 70°-100° | 90°-120° | 110°-135° |

During the use of electronic display screens and advertising display screens, ambient light will have a certain impact on the display effect of the screen, which will interfere with the recognition and clarity of the visual audience.

Especially in an environment with strong light and strong light contrast, it is necessary to solve the problem of reflection on the display screen, commonly known as anti-reflection.

EPAG PC Sheet Performance:

| Optical quality appearance |

| EPAG anti-glare sheet adopts optical grade PC sheet substrate, process surface treatment in1000 class cleanroom, which effectively avoiding impurities, black spots, stains and other problems on the sheet, and avoiding problems due to uneven coating thickness caused the rainbow problem. The sheet is double-sided with film, no quality issues such as scratches, dents, and scratches. |

| Touch smoother (paper-like touch) |

| EPAG anti-glare sheet, strictly control the surface roughness and wear resistance, the roughness Ra is controlled at about 1.3μm, suitable for powder writing, meanwhile making the touch smoother and more durable. |

| High resolution |

| EPAG anti-glare sheet can be customized with different light transmittance and haze according to requirements to effectively protect higher picture clarity. The surface of the product has finer graininess, lower roughness, and improved surface mprove the sharpness of the surface, improve the screen resolution, and make the image clearer. |

| Process parameter stability |

EPAG anti-glare sheet uses micro-nano structure formula through surface coating process to change the original optical composition of the surface of the sheet, the gloss, reflectivity and light transmittance have strong stability and evenness. Strictly control technical parameters to minimize parameter tolerances.

Parameters: haze tolerance ±1%, gloss tolerance ±1Gu, light transmittance tolerance ±1%. |

| Low reflection, reduced glare, safer |

| EPAG anti-glare sheet has a reflection rate of only about 1%, effectively reducing the surface gloss and visual interference of ambient light (reflected light), making light softer and healthier. |

| Expand the visual angle |

Nano-AG coating on the surface of EPAG anti-glare sheet can effectively reduce the reflectivity and make the reflected light more uniform.

Effectively expand the display angle and make the viewing range wider. |

| Remarkable experience |

1. No reflection, the picture is clearer, and the visual angle of the picture is wider.

2. The touch feels better.

3. No fingerprints after. touching. |

| Model | Material | Hardness | printability | Bendable | thermoforming | CNC | Type |

| EPAG10P | PC | HB | √ | × | × | √ | Nanopolymer |

| EPAG35P | HB | √ | × | × | √ | Nanopolymer |

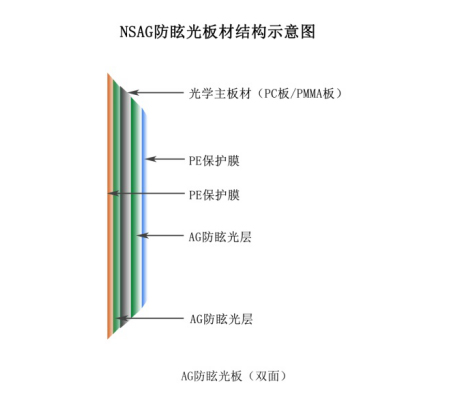

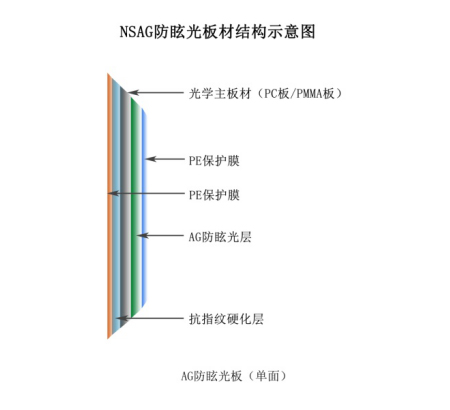

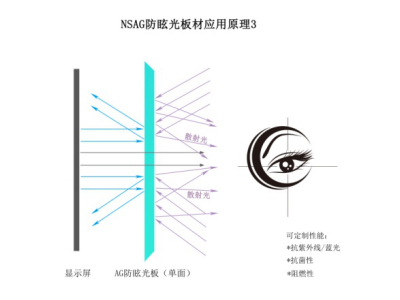

EPAG structure and application principles:

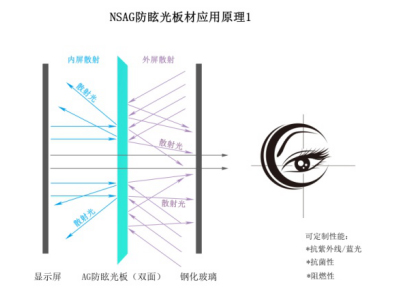

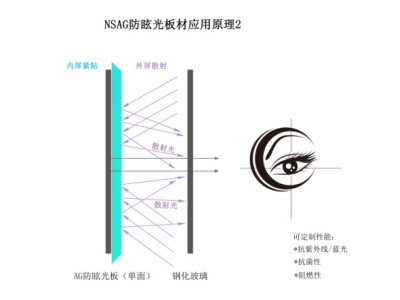

In the structure of electronic screens, if there is a certain distance between the LCD screen and the outer screen, the internal screen will produce a light spot effect caused by reflective light. At the same time, ambient light can also cause light and shadow phenomena outside the screen, affecting the clarity and viewing angle of the screen.

Therefore, according to the actual structure of the product, different AG anti-glare sheets need to be selected, including single-sided anti-glare and double-sided anti-glare.

EPAG PC Sheet SPECS:

| MODEL | COLOR | thickness (mm) | 0.5 | 0.8 | 1.0 | 1.5 | 2.0 | 3.0 | 4.0 | 5.0 | 8.0 | 10.0 | 12.0 |

| size (mm) |

| EPAG15P | CLEAR | 1000×2000 | b | b | b | c | a | | | | | | |

| 1200×2400 | c | c | b | b | a | a | b | c | c | c | c |

| EPAG35P | CLEAR | 1000×2000 | b | b | b | c | b | | | | | | |

| 1200×2400 | c | c | b | b | b | | | | | | |

a:Inventory b:Periodic c:Customized

1.If you need other thicknesses, lengths and widths, you can contact us for customization.

2.The sheet is covered with double-sided transparent PE protective film.

Application:

Industrial control/terminal display screens: ATM screens, terminal equipment screens

Advertising display screens: LED advertising display screens, lightbox advertising screens

3C electronic screens: PAD screens, phone cases, e-reader screens, electronic touch screens

Automotive/dashboards: car displays, dashboard panels, construction vehicle operation screens

Exhibition/signage/panels: signs, advertising panels, picture frame panels, QR code cards

Car dashboard panel

Car dashboard panel

Charging pile screen

Charging pile screen

Electric touch screen

Electric touch screen

E-reader screen

E-reader screen

Interactive whiteboard

Interactive whiteboard

Laptop screen cover

Laptop screen cover

Laptop screen guard

Laptop screen guard

Pad screens

Pad screens

Anti-glare light panel

Anti-glare light panel

EPAG PC Sheet Physical properties:

| Properties | Units | PC | TEST METHOD |

| EPAG15P | EPAG35P |

| Specific Gravity | - | 1.2 | 1.2 | GB 1033-70 |

| Light transmittance | % | 90 | 90 | ASTM D1003/GB/T 2410 |

| Haze | % | 15 | 35 | GB/T13452.3-1992 |

| Reflectivity | % | 1 | 0.9 | GB/T9754-2007 |

| Glossiness | Gu | 75 | 55 | GB/T14234-1993 |

| Roughness | μm | 0.5 | 0.8 | 500g pressure |

| Pencil hardness | - | H | H | GB T 9286-1998 |

| Adhesion | - | 5B | 5B | GB/T 7413-2018 |

| Tensile strength | MPa | 55 | 55 | GB/T 1040 |

| Elongation | % | 60 | 60 |

| Tensile modulus | MPa | 2200 | 2200 |

| Izod impact strength | kJ/m2 | ∨ 6 | ∨ 6 | GB/T 1043 |

| Heat deflection temperature | ℃-1 | 125 | 125 | GB/T 1634 |

| Coefficient | - | 6×10-5 | 6×10-5 | GB/T 1036 |

| Rate of heat dimensional change | - | 0.5 | 0.5 | GB/T 7413-2018 |

| Flame retardant grade | - | V2 | V2 | UL94 |

* The values above are a series of test results for some 2.0 mm thick sheets. The results provided here are just for reference.

□ Izod impact strength without notch.

∨ Izod impact strength with notch

Car dashboard panel

Car dashboard panel Charging pile screen

Charging pile screen Electric touch screen

Electric touch screen E-reader screen

E-reader screen Interactive whiteboard

Interactive whiteboard Laptop screen cover

Laptop screen cover Laptop screen guard

Laptop screen guard Pad screens

Pad screens Anti-glare light panel

Anti-glare light panel